THIS PAGE IS UNDER CONSTRUCTION

Bambook together with Eco concept group have designed this pouch

completely made of 100% recycled cotton.

With patented technology nxtile creates products that enable collabs to make a lot of impact. This way we save a lot of water, land and CO₂

because no virgin cotton has to be grown for this item.

Impact savings

by patented closed loop process

Network traceability

Bambook & easyessentials developed your bag and calculated the impact savings..

Bambook’s requirements are translated to specific raw material needs.

A specific mix of cotton waste is collected, reprocessed and checked.

The patented yarn of 100% recycled cotton is spun at a certified spinner.

The yarn is woven into high quality fabric in a solar powered certified factory.

Your bag is made in a socially certified location taking good care of the workers wellbeing and created by using a sustainable production process.

Your bag is transported over sea from Mundra to Rotterdam and forwarded to Bambook’s warehouse.

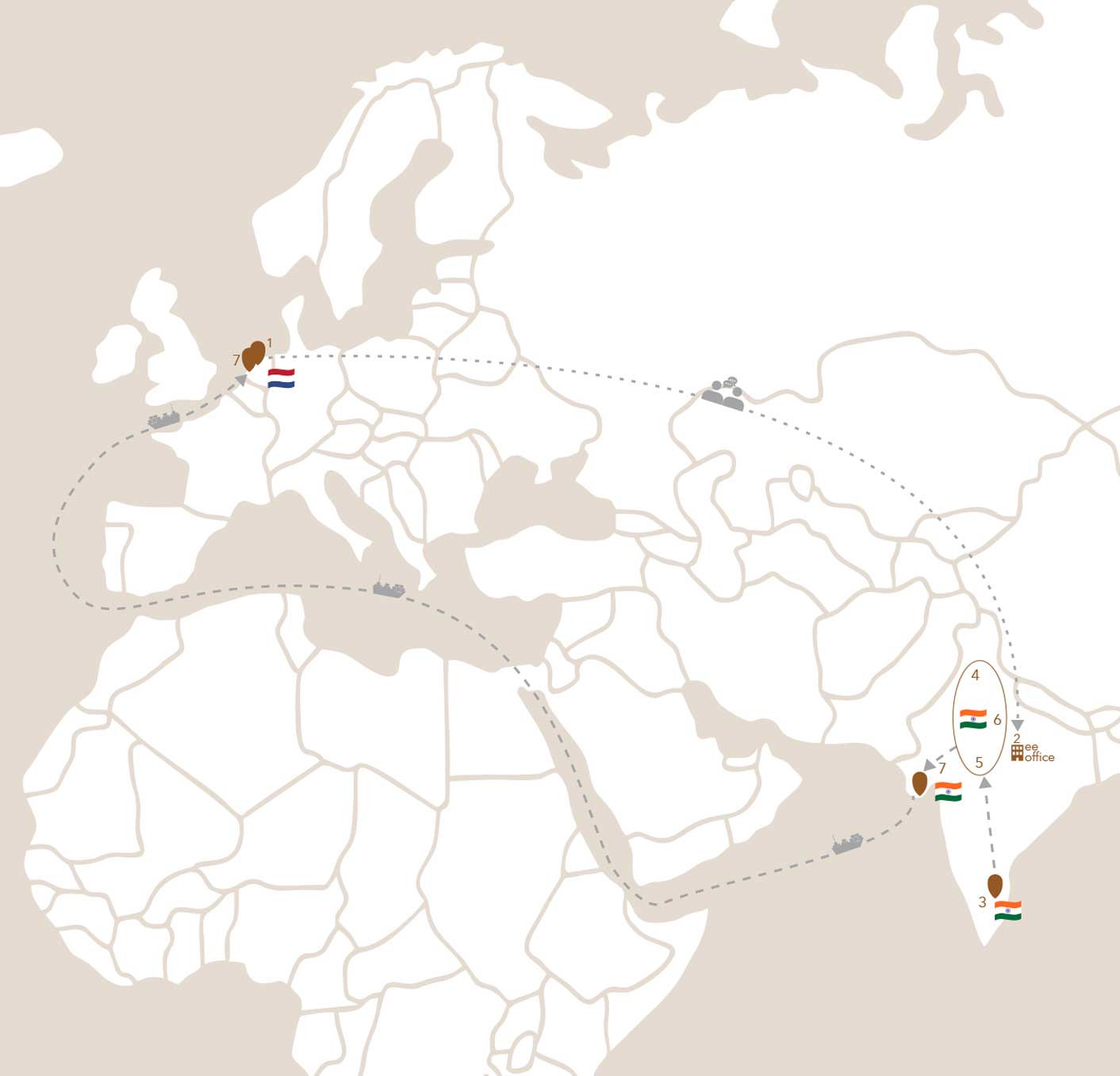

Step 1

Calculating impact:

Bambook & easyessentials developed your bag and calculated the impact savings.

Step 2

Product specifications:

Bambook’s requirements are translated to specific raw material needs.

Step 3

Waste collection and processing:

A specific mix of cotton waste is collected, reprocessed and checked.

Step 4

Spinning:

The patented yarn of 100% recycled cotton is spun at a certified spinner.

Step 5

Weaving:

The yarn is woven into high quality fabric in a solar powered certified factory.

Step 6

Stitching:

Your bag is made in a socially certified location taking good care of the workers wellbeing and created by using a sustainable production process.

Step 7

Transportation:

Your bag is transported over sea from Mundra to Rotterdam and forwarded to the Bambook’s warehouse.