Thank you for your interest in how the Superninja bag is produced.

This bag is made in a transparent network. Scroll down to learn more.

Thank you for your interest in how the Superninja bag is produced.

This bag is made in a transparent network. Scroll down to learn more.

Impact savings

By patented closed loop process

Impact savings

By patented closed loop process

Network traceability

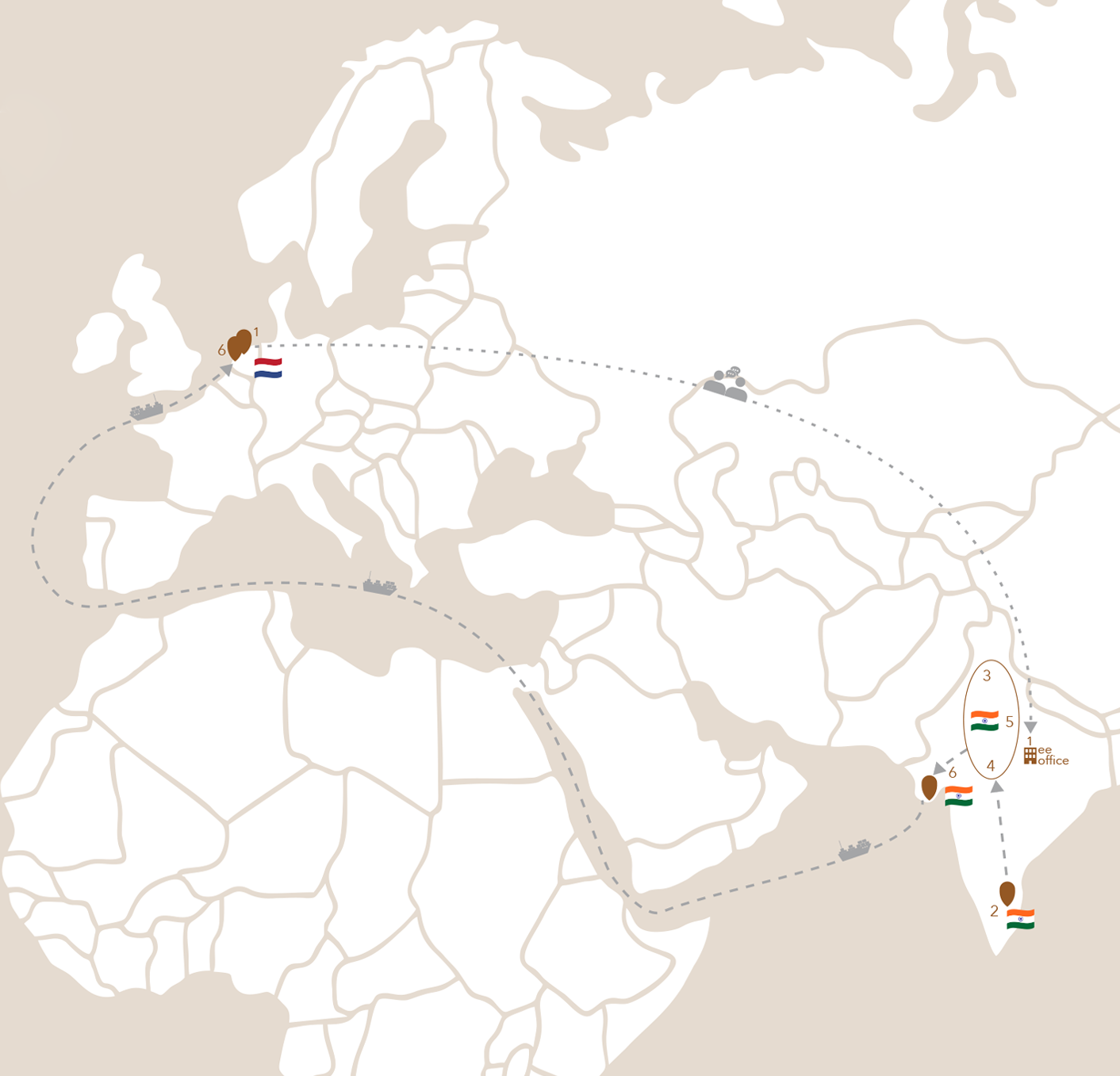

Superninja’s requirements are translated to specific raw material needs.

A specific mix of cotton waste is collected, reprocessed and checked.

The patented yarn of 100% recycled cotton is spun at a certified spinner.

The yarn is woven into high quality fabric in a solar powered certified factory.

Your bag is made in a socially certified location taking good care of the workers wellbeing and created by using a sustainable production process.

Your bag is transported by sea from Mundra to Rotterdam and from there to the textile printer in Amsterdam.

Your bag is printed locally in the Netherlands and then shipped to the Superninja warehouse.

Step 1

Product specifications:

Superninja’s requirements are translated to specific raw material needs.

Step 2

Waste collection and processing:

A specific mix of cotton waste is collected, reprocessed and checked.

Step 3

Spinning:

The patented yarn of 100% recycled cotton is spun at a certified spinner.

Step 4

Weaving:

The yarn is woven into high quality fabric in a solar powered certified factory.

Step 5

Stitching:

Your bag is made in a socially certified location taking good care of the workers wellbeing and created by using a sustainable production process.

Step 6

Transportation:

Your bag is transported by sea from Mundra to Rotterdam and from there to the textile printer in Amsterdam.

Step 7

Printing:

Your bag is printed locally in the Netherlands and then shipped to the Superninja warehouse.

For more info visit

FAQ

Making textile items from recycled cotton has been done for years now, but until recently, producers couldn’t guarantee strength and durability without adding virgin cotton, polyester or plastics. By contrast, easyessentials items are made through a patented process that uses 100% cotton waste and delivers high quality products. We are the first company in Europe to produce non-blended cotton waste textiles, which brings important environmental savings.

By using only cotton waste in the production process, there is no need to grow fresh cotton. This saves significant amounts of land and water and reduces CO2 emissions.

By using cotton waste, there is no need to grow fresh cotton as raw material for new textiles. Savings are calculated as the number of square meters (m2) of land that can now be used for other crops.

Growing cotton plants requires huge amounts of water. By using cotton waste, this water can be saved. These savings are calculated as the amount water (liters) that is no longer needed and can be used for other purposes.